Boron carbide, alias black diamond, is an inorganic substance. The chemical form is B₄C. It is one of the three toughest materials known in the world (after diamond and cubic phase boron nitride). Boron carbide is a black-gray powder with a Mohs hardness of about 9.5, a relative density of 2.52g/cm3, a melting point of 2350℃ and a boiling point of more than 3500℃.

Due to its low density, high strength, high temperature stability and good chemical stability, boron carbide is used in wear-resistant materials, ceramic reinforcement phase, especially in light armor, reactor neutron absorbent and other aspects.

The company mainly produces nuclear grade boron carbide products, technical indicators are customized according to the nuclear industry standards. Our company is a new "carbon thermal reduction method" process, step by step deoxidation, primary reaction, and then rapid crystallization method. The advantages of this method are high yield, uniform crystallization, uniform particle size, direct molding, eliminating the secondary processing link to the product pollution, thus greatly improving the quality of the product, so that B4C has better quality assurance.

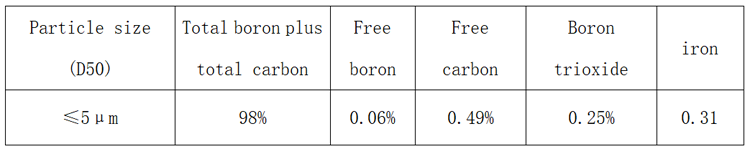

Physical and chemical indexes:

Packaging: Usually 20KG barrel, the inner packing is sealed with PE bag:

Application Field:

1. Neutron absorption and shielding materials in nuclear industry: Boron has a neutron absorption cross section of up to 600barn, so it is often used in the nuclear industry as the main material of choice in nuclear reactor deceleration element a control rod or nuclear reactor radiation protection parts.

2, composite armor material: using its light weight, super hard and high modulus characteristics, used as light body armor and bulletproof armor material, the use of boron carbide made of body armor, than the same type steel body armor is more than 50% lighter. Boron carbide is also an important bulletproof armor material for land armored vehicles, helicopter gunships and civil aircraft.

3. Superhard material: The ultra-high hardness and excellent wear resistance of boron carbide make it an important nozzle material. Boron carbide nozzle has the advantages of long life, relatively low cost, time saving, high efficiency and so on.

4. Sputtering target: boron carbide is often used to make magnetron sputtering target, which can be used as a target for sputtering film on the surface of glass, metal, plastic and so on.